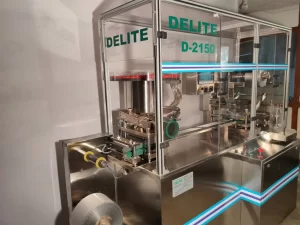

A class apart blister packing machine (Flat sealing) for pharma companies

Salient features of machine

- It is a very flexible machine, thus able produce pvc-alu as well as alu-alu strips

- Far more superior quality of blister strips obtained as compared to rotary forming and rotary sealing machine.

- Suitable for small batch production as well as research and development.

- Production per shift 170000 to 325000 fillings

- Extremely easy to operate blister packing machine and further has negligible maintenance.

- It is a combo machine hence it lowers the initial investment of pharma companies

- Optimum number of parts but very precision parts used on machine hence machine has negligible maintenance.

- Feeding system is far superior to gravity feeding system used in rotary machine.

- Very compact blister packing machine hence occupies very less space.

- Saves money for our customers every year in terms of manpower, maintenance, and further electricity cost.

- Machines have low noise level Our blister.

Technical details of blister packing machine model 2150C

| Forming area | 150 mm foil width & 100 mm advance |

| Base foil width / thickness | 150 mm / 0.25 mm to 0.4 mm |

| Base / sealing foil reel diameter | 440 mm / 210 mm |

| Sealing foil width / thickness | 146 mm / 0.025 mm |

| Forming depth | 14 mm |

| Strokes per minute | 40 |

| Length x Width x Height | 2580 x 945 x 1860 mm |

| Weight | 1100 Kg |

| Power requirement | Single phase 3 Kw 50Hz 4 wire |

| Compressed air | 10 Hp 35 Cfm (9 Kg constant pressure on machine) Air should be dry, clean & with 0 leakage. |

| Chilled water | 200 liters chilled water at 10 degree Celcius |

| Air dryer | 40 Cfm |

| Web advance | Rollers operated by servo motor |

| Automatic product feeding | Drum rotated by servo motor |

We have very high-tech inhouse manufacturing facilities to produce pharma machines.

Our infrastructure has 14 CNC machines and hence high level of accuracy is maintained. CNC machine includes vertical machining centers, CNC lathe, CNC wire cuts and further also computerized CNC spark erosion machine. We also have all the quality checking instruments which includes digital instruments. All the instruments are periodically calibrated and also records are perfectly maintained. Our design department is quipped with 3 seats of Unigraphics software thus integrating design and manufacturing. Design department has highly qualified and also experienced engineers.

Other machines for pharma companies